21 Aug How Modular Fixturing for Welding Delivers Speed, Flexibility, and Lower Costs

Many manufacturers struggle with the limitations of part-specific weld fixtures, which can slow down new product introduction, increase costs, and reduce flexibility on the production floor. Each new design or change in demand often requires time-consuming fixture development, creating delays that directly impact delivery schedules and customer responsiveness. At KL Engineering, we address these challenges by implementing modular fixturing systems that provide the adaptability required to support both prototype development and full-scale production without unnecessary downtime or rework.

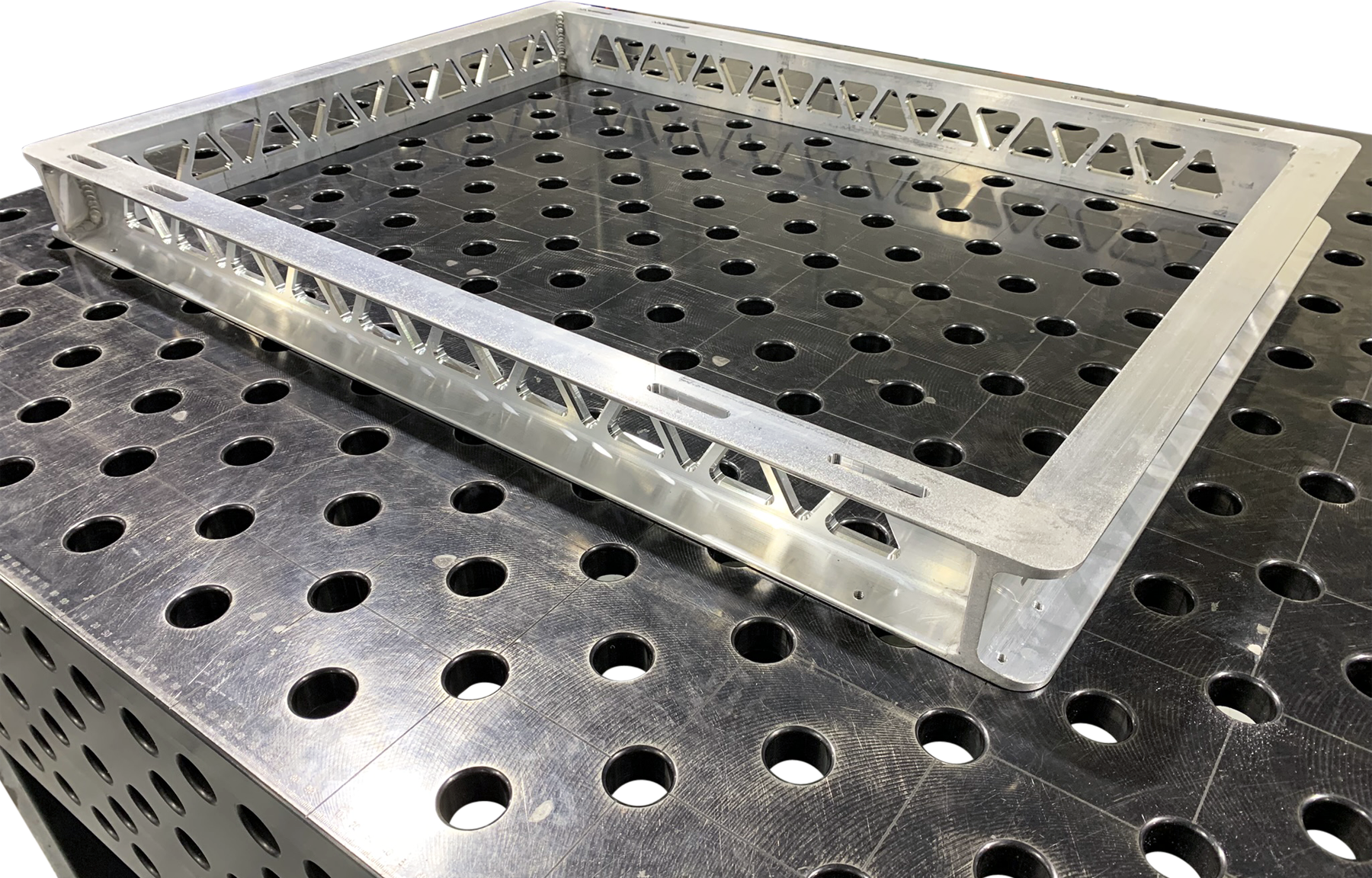

KL Engineering has advanced beyond the limitations of part-specific weld fixtures by standardizing on modular fixturing systems. This approach enables rapid reconfiguration across a wide range of projects, supporting both first-article prototypes and full-rate production runs. By eliminating the need to design and fabricate unique fixtures for each part, we reduce setup time, increase process repeatability, and ensure greater flexibility to meet evolving customer requirements.

That means when demand shifts, or when a customer needs a new weldment turned fast, we don’t wait on fixture design and fabrication.

Why Modular Fixturing Matters in Welding

Improved Lead Times

Since new parts do not require dedicated fixtures, the transition from design to weld is significantly streamlined. This capability makes modular fixturing especially advantageous for customers managing short-run programs, rapid prototyping needs, or projects with frequent design revisions.

Built-In Flexibility

Our modular weld cells allow us to handle a wide range of part geometries without slowing down production. Whether it’s a one-off prototype or a repeat production run, we can keep the same high level of repeatability and weld quality—without waiting for tooling.

Why Traditional Dedicated Weld Fixtures Create Bottlenecks

Dedicated fixtures are designed for a single part or assembly. While they provide repeatability, they also lock a shop into long lead times and limited flexibility. Every new part requires a new fixture—delaying production and tying up resources.

The Hidden Costs of Fixture Designs

Part-specific fixtures don’t just take time to engineer and build—they also carry hidden costs:

- Engineering hours spent on fixture design

- Fabrication costs for each new fixture

- Storage space to keep unused tooling between programs

- Maintenance costs to keep fixtures accurate over time

Over the life of a program, these costs add up, eating into margins and slowing responsiveness.

How Modular Systems Eliminate These Limitations

Modular fixturing removes the bottleneck. With standardized bases, locating features, and clamps, weldments can be set up using a common system that adapts to many part families. Instead of waiting weeks for a new fixture, operators can reconfigure existing tooling in a matter of hours – keeping CNC machines and weld cells running at full capacity.

Let’s Build the Right Solution – Together.

At KL Engineering, capability and flexibility unite to serve one purpose: your goals. We don’t believe in one-size-fits-all. Instead, we tailor every project to fit your unique needs, seamlessly aligning with your processes and priorities. Ready to move forward with a partner who adapts to you? Contact us today to get started on your next project.