23 Sep Weld Integrity: The Foundation of Safety in Aerospace and Defense

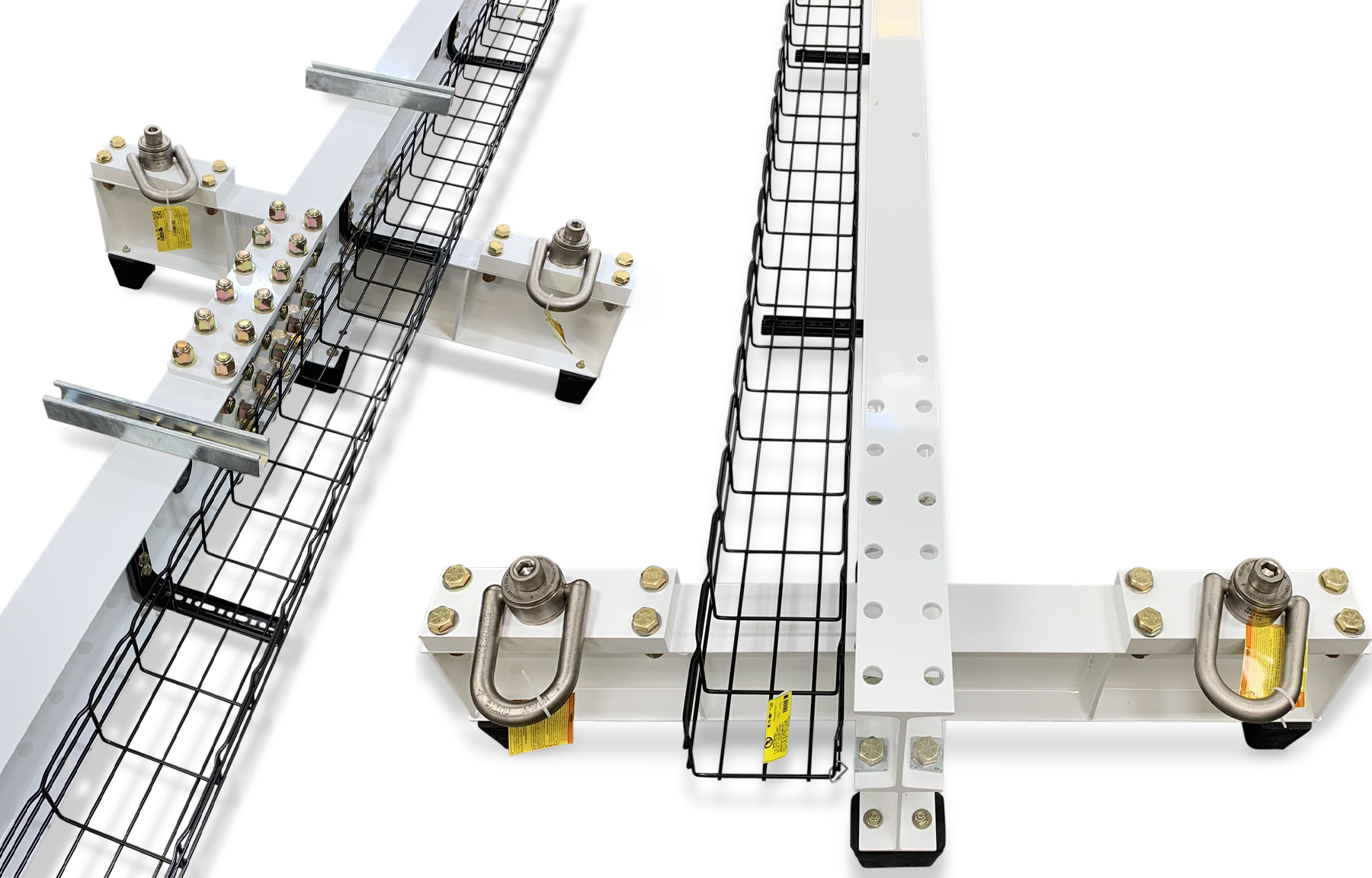

In aerospace and defense applications, there is no room for compromise. Every component must withstand demanding environments where failure is simply not an option. Among the most critical factors that determine the reliability of these systems is weld integrity.

Poor welds may look harmless on the surface, but can lead to catastrophic consequences when subjected to real-world stresses. Under conditions of extreme load, vibration, and thermal cycling, even the smallest defect can propagate into a structural failure. That is why weld quality in aerospace and defense is far more than a production detail — it is a matter of safety, mission success, and long-term performance.

Why Weld Integrity Matters

- Load-bearing performance: Welds often connect structural elements that carry high stresses. A compromised joint can weaken the entire system.

- Resistance to vibration: Aircraft and defense vehicles are exposed to intense vibration profiles during operation. Deficient welds can fatigue and fail under repeated stress.

- Thermal cycling durability: Components face wide temperature ranges — from high-altitude cold to engine-adjacent heat. Robust welds ensure dimensional stability and prevent cracking.

Beyond Welding: Inspection as a Critical Partner

Ensuring weld reliability requires more than just skilled technique. Rigorous inspection processes — including visual examination, non-destructive testing (NDT), and dimensional verification — confirm that each joint meets stringent standards before it ever enters service.

Visual Inspection: The First Line of Defense

Before advanced testing comes into play, visual examination helps identify surface flaws such as cracks, porosity, or undercuts. Skilled inspectors use magnification, lighting, and weld gauges to spot issues early.

Non-Destructive Testing (NDT) Methods

Techniques like ultrasonic testing, radiographic imaging, magnetic particle inspection**, and dye penetrant testing allow defects to be detected without damaging the weld. Each method has unique strengths depending on material, thickness, and application.

Dimensional Verification and Tolerances

Precise measurements ensure that welded assemblies meet required specifications for fit, alignment, and load-bearing capability. Tools such as calipers, coordinate measuring machines (CMM), and laser scanners play a role here.

Documentation and Traceability

Inspection is not only about detection but also about recordkeeping. Traceable reports provide customers and regulators with assurance that every weld meets compliance and quality standards.

Inspection as a Continuous Process

Inspection doesn’t stop after production. Periodic in-service inspections and maintenance checks extend the lifecycle of equipment, ensuring ongoing safety and reliability in demanding environments.

Let’s Build the Right Solution – Together.

At KL Engineering, capability and flexibility unite to serve one purpose: your goals. We don’t believe in one-size-fits-all. Instead, we tailor every project to fit your unique needs, seamlessly aligning with your processes and priorities. Ready to move forward with a partner who adapts to you? Visit our website or contact us today to get started on your next project: www.kle-inc.com.