15 Nov Why Precision Machining and Mechanical Insight Come Before Sensors and Servos

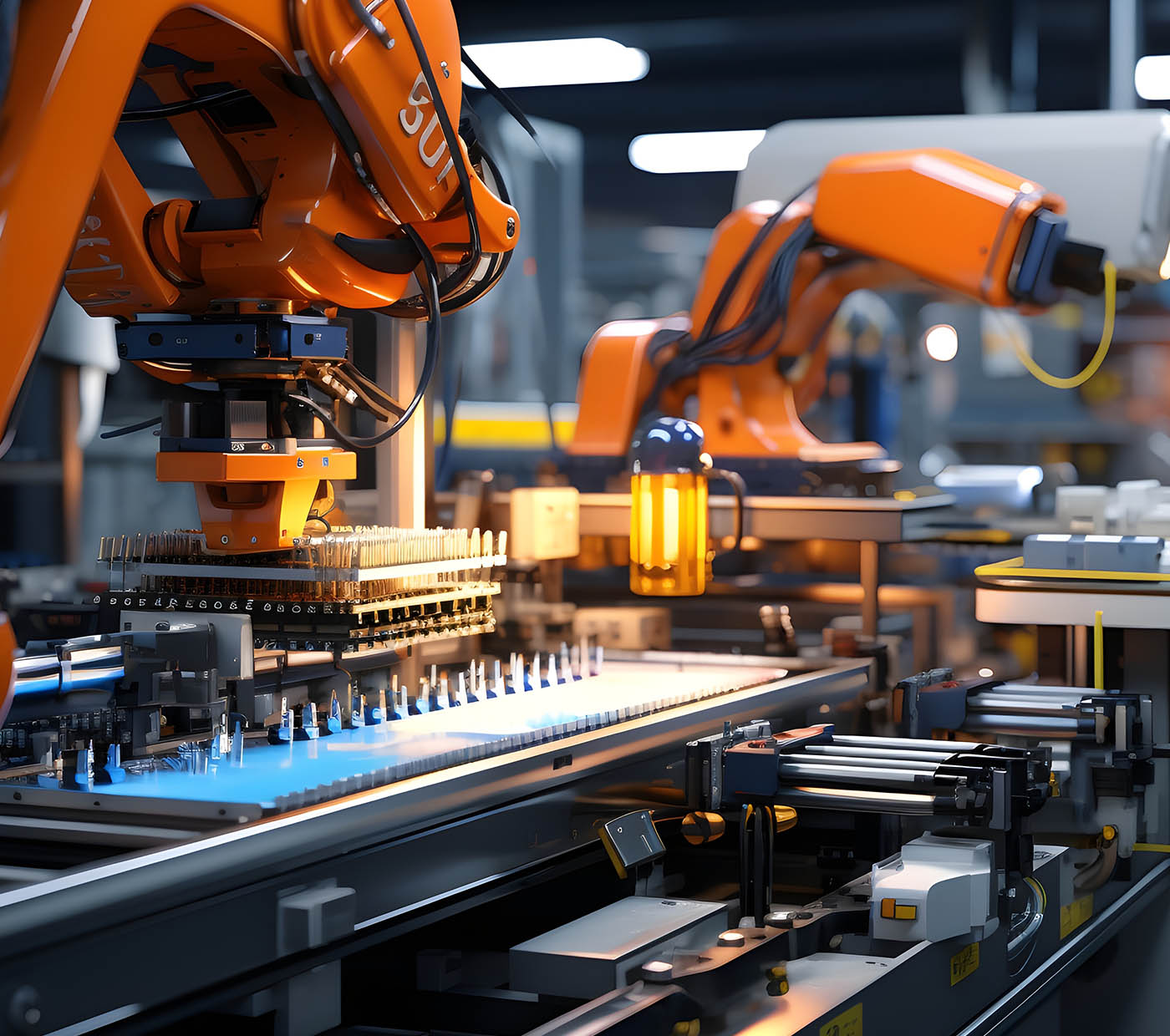

Automation dominates headlines—robotics, smart actuators, AI-driven controls— so it’s become easy to believe that sensors and servos are where automation truly begins. But the truth is simpler and far more fundamental: before you add intelligence to a system, you must understand its motion. Every reliable automated machine, no matter how sophisticated, is built on precise mechanical behavior. And achieving that level of mechanical clarity starts with machining, alignment, and a deep understanding of how physical systems actually move.

At KL Engineering, we’ve learned that great automation is never defined by the components you add later—it’s defined by the foundation you build first. When mechanical systems move exactly as intended, automation becomes smoother, more predictable, and far more dependable.

Before Automation, There Must Be Motion

Automated systems live or die by their mechanical integrity. If a system binds, flexes, vibrates, drifts, or deflects, no amount of sensors or closed-loop control will save it. In fact, adding electronics to a mechanically unstable system often makes the problems harder to diagnose—and more expensive to fix.

That’s why the first step in automation isn’t programming; it’s physics.

Understanding motion means understanding:

- How forces transfer through assemblies

- How tolerances stack when multiple components interact

- How friction, backlash, or deflection impacts movement

- How materials behave under load, heat, or repetitive cycling

- How wear patterns change over time

If these fundamentals aren’t controlled first, sensors end up compensating for mechanical errors instead of enhancing performance. Motion becomes something the controls system must fight instead of manage.

The Precision Machining Advantage

This is where precision machining becomes inseparable from automation engineering. A machine can only be as accurate as the components inside it. When linear rails aren’t perfectly aligned, bearings aren’t perfectly seated, or housings aren’t perfectly flat, the motion path degrades long before software ever enters the equation.

Precision machining ensures that:

- Mating surfaces are truly flat and parallel

- Holes align with the centerlines they’re designed to support

- Assemblies locate repeatably and consistently

- Moving components travel smoothly, without deviation

- Joints, pivots, and bearings operate without internal stress

When the mechanical platform is flawless, motion becomes predictable. And when motion is predictable, automation becomes infinitely easier.

Mechanical Insight: The “Invisible Skill” Behind Automation

Sensors measure behavior. Servos correct behavior.

But machinists and mechanical engineers predict behavior.

This insight is gained through years of building mechanisms, testing assemblies, and troubleshooting motion problems that don’t appear in CAD. Experienced machinists and design engineers know how a system should move—and they can instantly identify when real motion deviates from that expectation.

This is where machining and automation intersect:

- Machinists understand how tiny inaccuracies compound into motion errors

- Engineers understand the geometric relationships that determine smooth travel

- Together, they create systems where the physical motion matches the design intent

Without this partnership, automation becomes an exercise in chasing symptoms instead of controlling the system.

Automation Becomes Easier When Mechanics Are Right

When motion is mechanically sound, control systems suddenly don’t have to work as hard. A system that moves cleanly requires fewer sensors, less compensation, and simpler programming. Cycle times stabilize. Accuracy improves. Reliability increases. Maintenance costs drop.

In other words:

Automation works best when the mechanics are dialed in first. That’s why at KL Engineering, our approach to automation starts on the shop floor—with the components that define how a system will behave long before a servo ever turns on.

Let’s Build the Right Solution – Together.

At KL Engineering, precision and adaptability converge to advance your objectives. Every project is custom-engineered to align with your processes, priorities, and vision – because one-size-fits-all solutions are never enough. Partner with a team that molds to your needs and delivers results engineered for you. Explore how we can elevate your next project: www.kle-inc.com